Small Run Batch Deutz OO9 kit

SRB001 Freelance DEUTZ Style 0-4-0DM

Part of the premise for Stuart’s kits is that he will only do small runs. That’s how he wants to do it and he has gained a great deal of knowledge of his late father and the other members of the GDNGRS who manufacture kits — I am one of the few who doesn’t! So if you see one of these kits running it will probably be a rare sight but also will run really well.

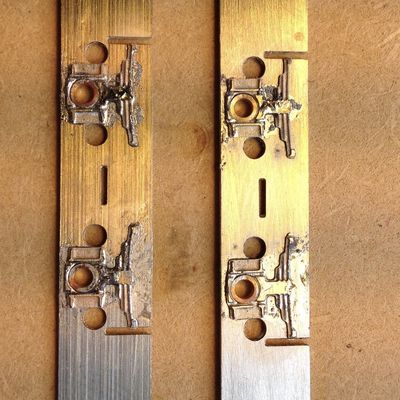

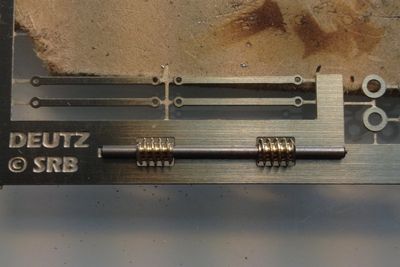

The kit comprises of a nickel silver and a brass etch, and several bags of small parts. The instructions come on a small cd — I had to request a PDF from Stuart as I no longer have a functioning CD reader or one that will work with small format CDs.

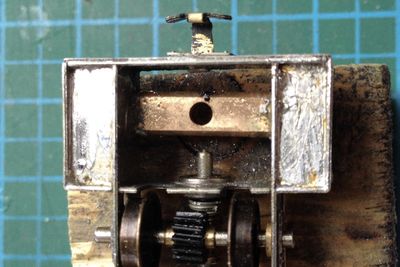

So far I am enjoying building this kit. The instructions are very well thought through but you do need to have the right gear to get the best out of it and if you have never soldered a brass kit together before then this shouldn’t be your first kit to try it on! The specialist tools you will need are a 16BA tap and a good set of broaches — I have a cheap set and am now on the lookout for a much better set of broaches as the cheap plastic handles on mine keep shattering.

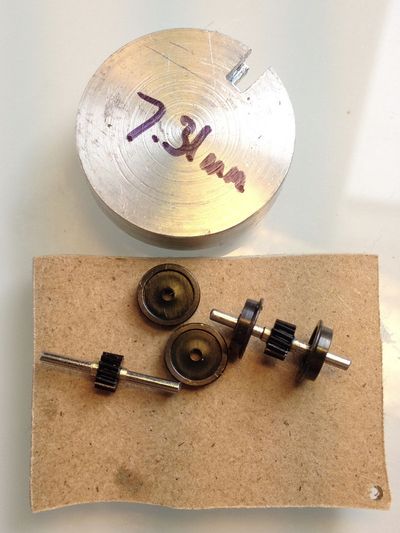

One of the first things I wondered was with the brass sleeve you put on the axle — this could have been 7.3mm in length thus giving the ideal back to back for the wheels though perhaps having room to adjust the wheels might be more important — just a thought as I don’t have any prior experience to call on.

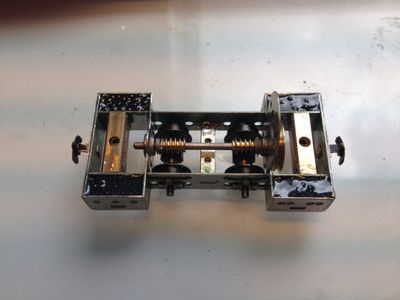

The most difficult part was the construction of the cranks and the instructions do alert you to this and are clearly written to help you go through this. Soldering the three frameworks with the cranks together before you actually solder the cranks together really helps. I did that and tapped the holes for the crank pins while it was still on the fret. the instructions state you should broach the axle holes in the cranks while on the fret as well but I had no spare rod of the axle size and there isn’t room to offer up the axles in the frame so I did the broaching after the cranks were cut out of the fret.

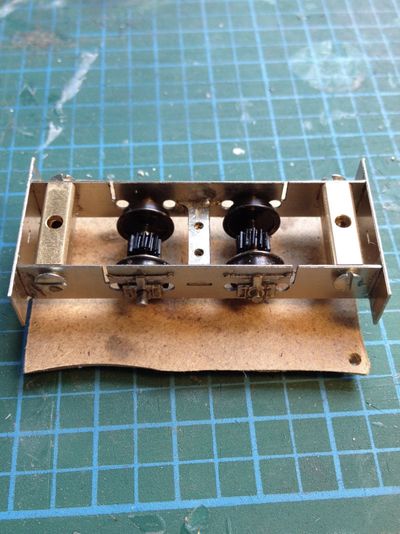

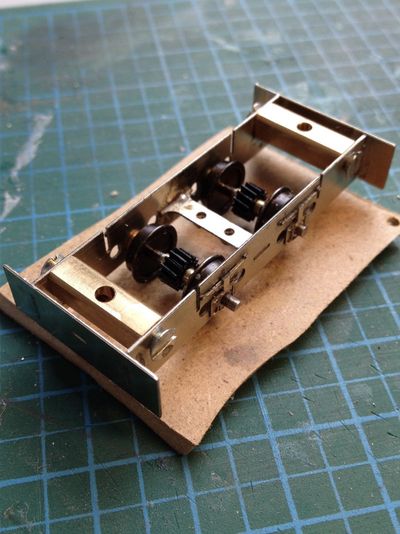

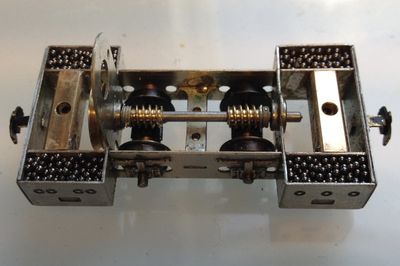

When I first examined one of Stuart’s prototypes for this kit I was pleased with the weight he had managed to pack in. The corner ballast boxes can indeed be bulked up with lead and to achieve this I capped the bottom of each corner with some spare brass sheet cut to size and soldered in. I then filled each with lead shot and covered in epoxy glue. this has provided a good amount of weight into the frame which will give the loco a much smoother ride.

Small Run Batch Deutz OO9 kit Gallery

And there is more...

Next post: Whitesands Quay first outing

Previous post: Whitesands Quay - Row of cottages - chimney pots